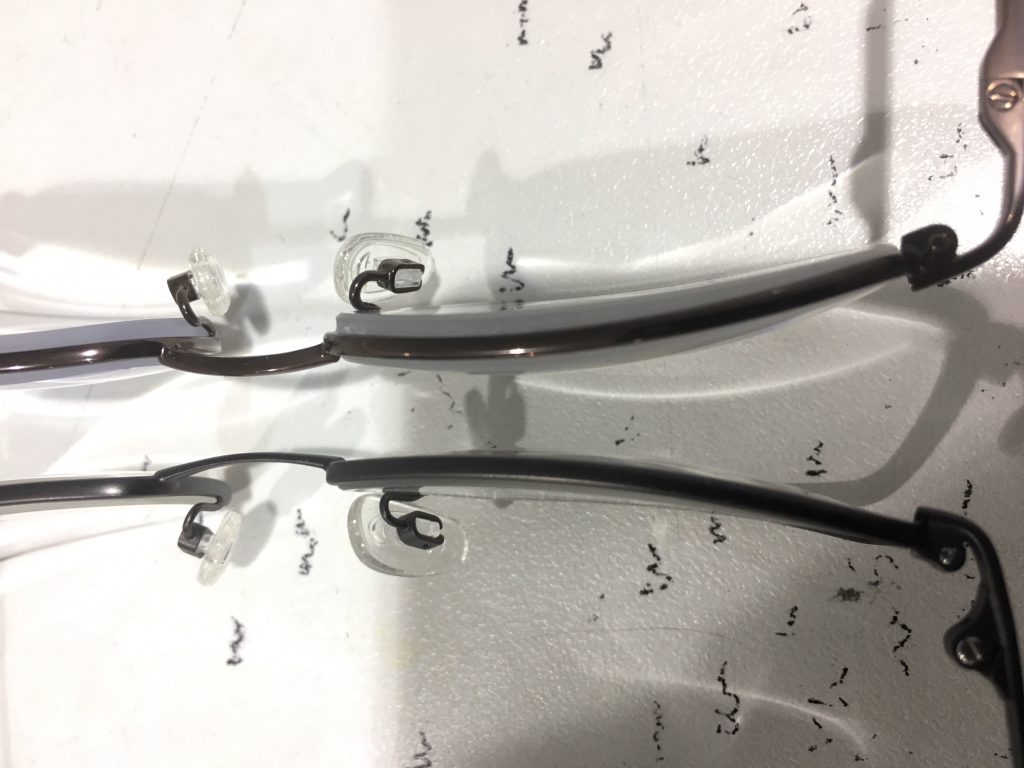

You may have heard of the term ‘grind lenses’ but probably don’t really know what it really means. The same may apply to the term ‘stock lenses’. Anyway, stock lenses are finished on both the front and back surface, come in various powers including correction for astigmatism and are delivered as a round blank of perhaps 65 or 70mm in diameter. The lens is then shaped by a machine so that it can be fitted into a frame. The picture below is of two pairs of glasses with the one above made in stock lenses and the one below in grind. Look at the thickness difference!

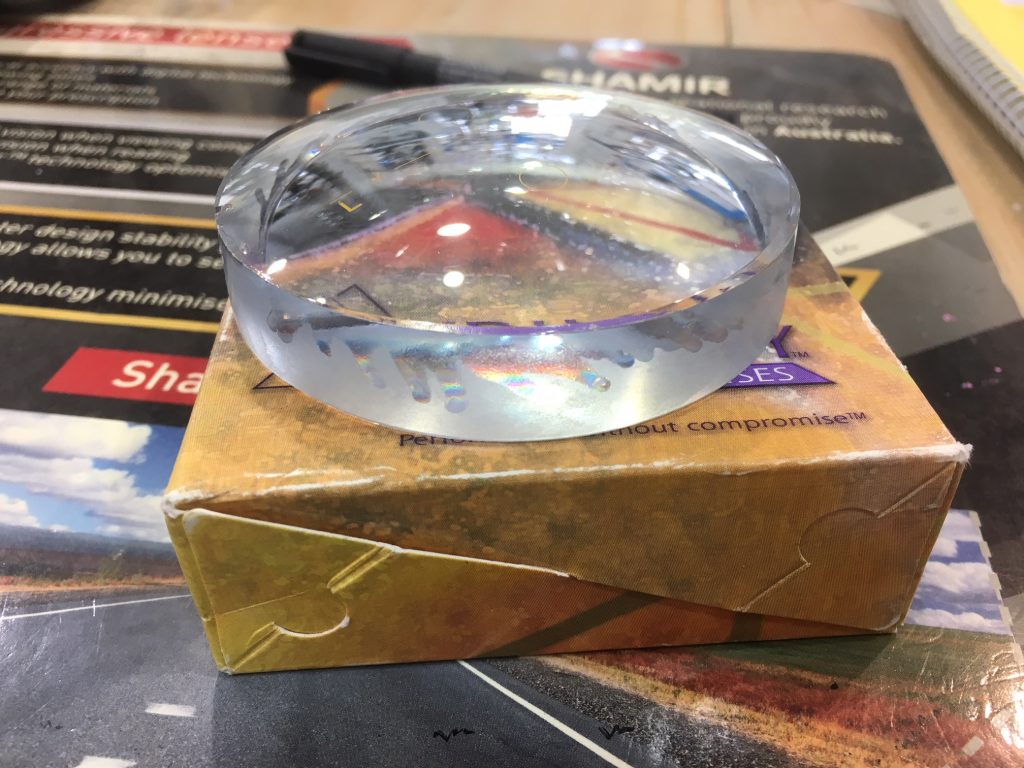

Grind lenses begin as a ‘semi finished’ blank, whereby the front surface only is finished and the back surface is finished by a machine called a generator. Because grind lenses are specially surfaced, they can be made to the correct thickness for the dimensions of the frame and a thinner, more comfortable pair of glasses can result. Pictured below is a semi-finished lens blank as is straight out of the packet.

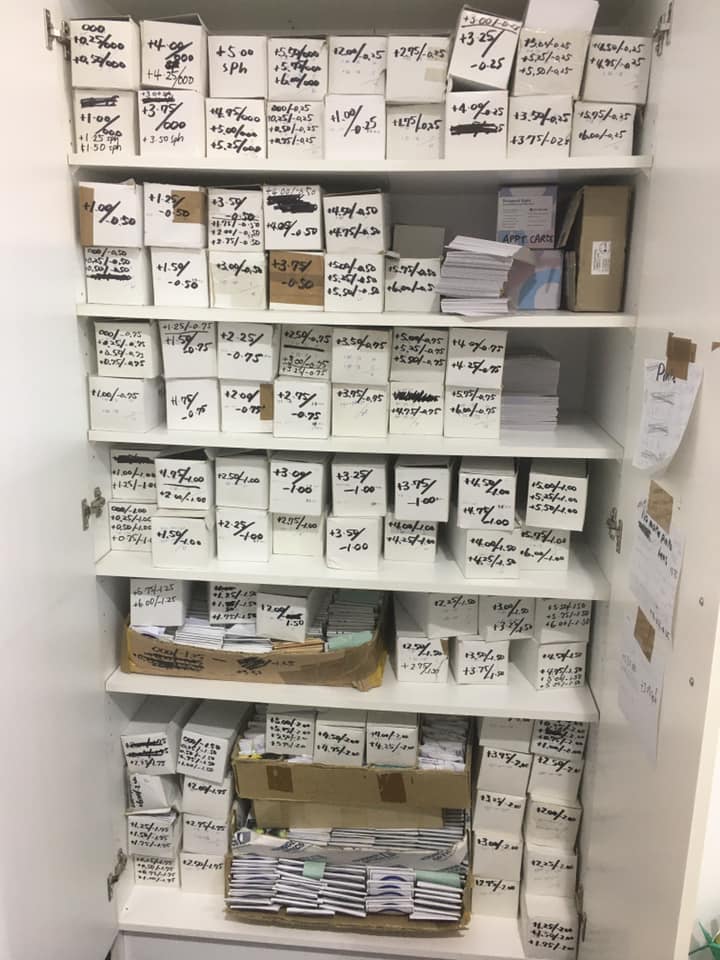

Here is our stock lens cupboard. Shown are a range of plus powers only in various corrections for astigmatism.

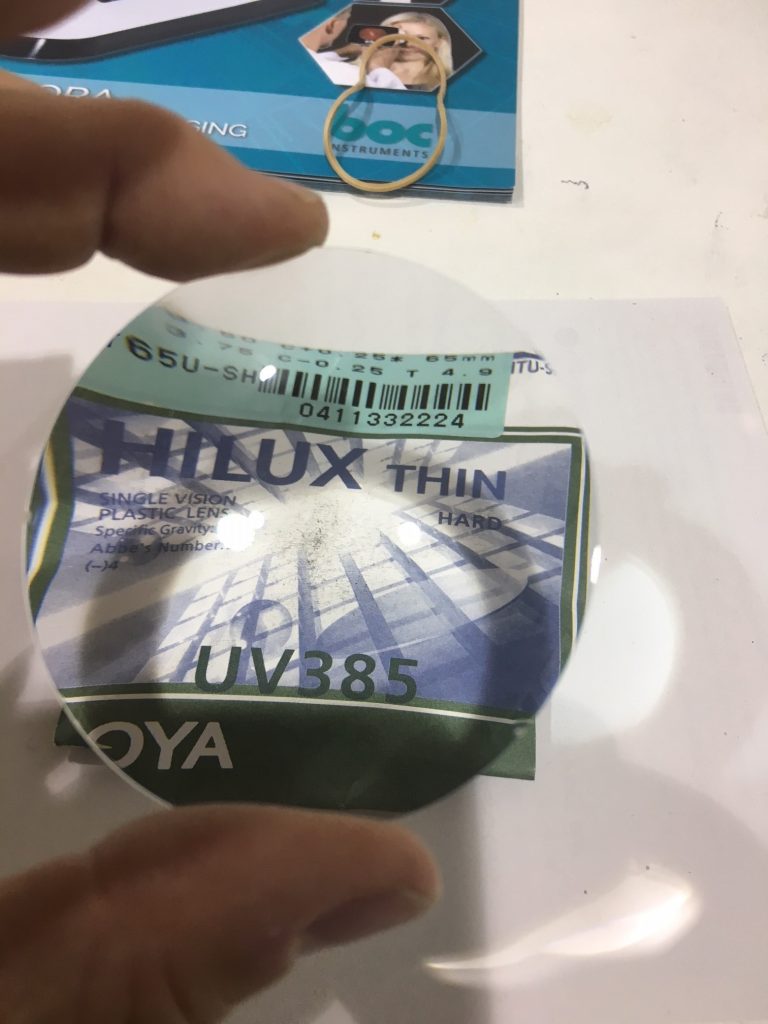

Below is a stock lens before being cut.

Sometimes however, whether the lens is grind or stock makes no difference. It all depends on the prescription, frame size, distance between the pupils, amount and angle of astigmatism. Only a well trained and experienced optical mechanic or dispenser can interpret all that information and really know which way to go. Doing the wrong thing can result in ugly, heavy glasses or unnecessary expense.

Published by